Metal Powders (e.g., Iron, Steel, Aluminum) moisture meter|springer metal powder : service This article evaluates the water content in titanium powders using different techniques (gravimetry, Karl Fischer titration, quantification of volatiles with a relative humidity . webJunte-se aos milhões de usuários em milhares de organizações globais que usam o .

{plog:ftitle_list}

Resultado da Confira a lista das competições que estão em andamento no Brasil e no mundo e veja também os campeonatos já encerrados na temporada 2020.

water content in metal powder

Atomization is the most common method for producing metal and pre-alloyed powders, or powders consisting of two or more elements alloyed . This article evaluates the water content in titanium powders using different techniques (gravimetry, Karl Fischer titration, quantification of volatiles with a relative humidity . This systematic review presents different concepts involving L-PBF and DLD manufacturing and the application of metal powders. The methods used to produce and .

The current review gives insight into different metal powder manufacturing methods, the essential properties of metal AM powders, how the AM process can change and influence .

springer metal powder

properties of powder in metal

Steel, stainless steel, aluminum, copper, nickel, cobalt, and titanium alloys are common. Applications – Alloy powder is used to manufacture PM parts, thermal spray . To evaluate such effects, these powders need to be characterized, tested, and analyzed at critical stages of their lifecycles. This paper provides a review of the current state .Some examples of metal powders commonly used in manufacturing products: Aluminum Powder – Its flammable properties make it ideal for fireworks and pyrotechnics. Bismuth .

We develop dedicated high performance steel and nickel alloy materials for use in specific industry applications such as High Pressure Die Casting and Plastic Injection Molding. All of our AM powders are available in particle size ranges .

Metal alloy powders are particulate materials composed of two or more metals manufactured via atomization or chemical reduction into fine spherical powders ideal for industrial applications. Key benefits of using metal .Turn to Metal Powders USA in Gig Harbor, WA. We offer aged bronze, aluminum, brass, and more. . We supply a variety of metal powders, including aluminum, antique bronze, brass, bronze, copper, iron, nickel silver, . The impact of moisture on flowability and spreadability is discussed. More notably we also present research on the impact of moisture on built nickel-base material. One lot of a newly opened Hastelloy X (HX) L‑PBF powder was split into two equal batches. One batch was moisturized using a programmable climate chamber, the other was untreated. We built bars .

Pre-alloyed Steel Powder; Base composition: Various metal systems, e.g. stainless steel, tool steel, nickel alloys: Iron or iron + carbon (steel) Alloying elements: One or more metals added to tailor properties: Carbon + trace alloying elements like Mn, Ni, Mo: Production method: Atomization of molten alloy: Pre-blending iron and graphite .They can be grouped by their major alloying elements (e.g., stainless steels contain considerable amounts of chromium), or by the percentage of all alloying elements that the steel contains (e.g., high-alloys steel typically contains more than 8 % alloying elements, while low-alloy steel has less than 8 %). #5. STAINLESS STEEL.

1L Differential Scanning Calorimeter convenience store

Laser powder bed fusion (L-PBF) and direct laser deposition (DLD) are the two main processes currently used in the additive manufacturing (AM) of metals. For both methods, metal powders are used as feedstock, and they must present specific physical and chemical properties to ensure optimal processing and reliable and reproducible printing results. Particle .

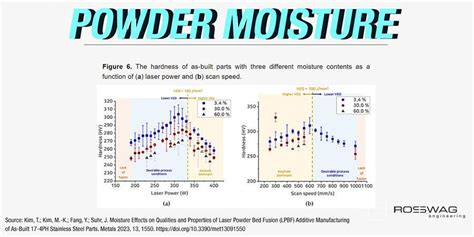

The moisture content of metal powders can have a negative influence on rheological powder properties and the properties of the final part. . This study compares 8 different flowability testing .The following processes can be used to produce metal powder: [6] Direct reduction is the result of blending carbon with iron oxide ore, heating the mixture, removing the sponge iron from the carbon, grinding it, annealing it, and regrinding to make the powder form usable for manufacturing. Gas atomization occurs when a molten metal is passed through a passageway .Metal powders intended for powder-bed based additive manufacturing (AM) have properties critical for ensuring robust processes with high product quality. The water content/moisture of the powders is one of these properties. RISE offers analysis of the water content in metal powder with great accuracy using Karl Fischer Titration. Iron powder is highly magnetizable and exhibits high permeability. It also has a relatively high density compared to other metal powders. Additionally, iron powder displays excellent electromagnetic properties. Some of the key properties of iron powder include: High magnetizability and permeability; Density of 7.86 g/cm3; Melting point of 1538°C

304L Stainless Steel Powder; 316L Stainless Steel Powder; 409L Stainless Steel Powder; 410L Stainless Steel Powder; 430L Stainless Steel Powder; 434L Stainless Steel Powder; Specialty Powders. Surface coating / Hardfacing; T-400 • T-800 (Tribaloy®) Powders; C-276 • C-22 • C • B • X (Hastelloy®) Powders; 17-4 PH® Alloy Powder; Tool . The evolution of Hausner ratio and apparent density was studied. Climate conditions, shown in Table 4, were chosen to represent process conditions linked to real powder handling in the L-PBF process chain (e.g. 44%/22°C/24 h), but also to consider extreme conditions (e.g. 95%/22°C/24 h).

Global Producers of Aluminum Powders Since 1958. One of the leading aluminum powder manufacturers offering a full-range of coarse to fine aluminum powders for Powder Metallurgy, Metal Injection Molding, as well as Aluminum Alloy Powders for Additive Manufacturing.CONDENSATE WITHIN METAL POWDER BED FUSION Published by Sintavia, LLC, in partnership with the Additive Manufacturer Green Trade Association (AMGTA) and Triumvirate Environmental, Inc. . steel, titanium, and aluminum alloys. Some of these alloys, such as nickel (Inconel 718 and Inconel 625) and steel (316L and 17-4PH), .Global Producers of Aluminum Powders Since 1958. One of the leading aluminum powder manufacturers offering a full-range of coarse to fine aluminum powders for Powder Metallurgy, Metal Injection Molding, as well as Aluminum Alloy Powders for Additive Manufacturing.

United States Metal Powders, Inc. markets its aluminum powders worldwide, offering a full-range of coarse to fine aluminum powders. The company takes pride in its excellent reputation for consistent quality, dependable deliveries .

Global Producers of Aluminum Powders Since 1958. One of the leading aluminum powder manufacturers offering a full-range of coarse to fine aluminum powders for Powder Metallurgy, Metal Injection Molding, as well .

©2002 John Wiley & Sons, Inc. M. P. Groover, “Fundamentals of Modern Manufacturing 2/e” Production of Metallic Powders •In general, producers of metallic powders are not the same companies as those that make PM parts •Virtually any metal can be made into powder form •Three principal methods by which metallic powders are commercially .POWDER PORTFOLIO. Our material portfolio goes beyond standard material grades commonly used in Additive Manufacturing applications. We develop dedicated high performance steel and nickel alloy materials for use in specific industry applications such as High Pressure Die Casting and Plastic Injection Molding.. All of our AM powders are available in particle size ranges to .

Laser-based additive manufacturing processes, particularly direct energy deposition (DED), have gained prominence for fabricating complex, functionally graded, or customized parts. DED employs a high-powered heat source to melt metallic powder or wire, enabling precise control of grain structures and the production of high-strength objects. However, common . Metal enclosure powder coating involves applying dry and free-flowing powder to the enclosure surface using electrostatic charges. Properly powder coated metal enclosures have very high resistance to peeling and cracking in addition to high chemical, corrosion and abrasion resistance. Today’s guide explores everything about powder coating electrical . But for large structural fabrications, traditional casting or deformation processing of steel is better. Iron Powder Material 4 FAQ. Q. How is iron powder classified based on particle sizes? Iron powder is commercially classified by mesh sizes into: Coarse grades – below 100 mesh size (149 microns) Fine grade – 100 to 400 mesh (37 to 149 . The powder metallurgy process works on many metals, including aluminum, iron, copper, and stainless steel. Aluminum-based powders, on the other hand, have gained increasing popularity in powder metallurgy in recent years. Several factors make aluminum so popular, including its unique properties and its cost-efficient and efficient production .

Iron based low carbon: MSSA Ni 109. A Ni-Al primary composite bond coat powder containing typically 5% Aluminum. When flame sprayed, the particles go through a metallurgical phase change that allows self bonding to clean oxide free metal surfaces except Copper. Used as a bond coat on properly prepared surfaces to a thickness of 100µ to 200µ .How metal powder is used in manufacturing Metal powder products are created using powder metallurgy with a variety of processes including: Powder forging Hot isostatic pressing Metal injection Electric current assisted sintering Additive manufacturing (3D printing, selective laser sintering etc.) {{cta(‘2fb65aec-a9b3-44cb-a181-af83b2fa887d’)}} Products made from .

The density of common metals such as iron is 7.87 g/cm3, mild steel is 7.85 g/cm3, 304 stainless steel is 8.0 g/cm3, aluminum is 2.7g/cm3, copper is 8.93 g/cm3, gold is 19.3 g/cm3, silver is 10.49 g/cm3, for more metals, please view the metal density chart and table below. Common & Less Common Metal Density Chart / Table Introduction. Metal powders are finely divided metal particles that are used in a variety of manufacturing processes.Metal powders can be made from various metals like iron, aluminum, copper, nickel, and more. They have widespread applications across many industries including automotive, aerospace, electronics, chemical, pharmaceutical, and others.

metal fuel energy density renewables aluminum iron oxide magnesium hydrogen economy stirling engine iron economy green energy iron Alexander Hellemans The Conversation (0)

powder in metal manufacturing

18 de fev. de 2021 · Mobdro is a free app for watching Movies, TV Shows and Live TV channels. Download latest Mobdro APK for Android, Firestick, Smart TV and Chromecast.

Metal Powders (e.g., Iron, Steel, Aluminum) moisture meter|springer metal powder